TIR Lens

A TIR lens is an optical lens built on the principal of total internal reflection (TIR). TIR lenses collimate light, sending out a concentrated beam of full intensity. They are used in a wide variety of applications, including collimating the beams from high power LEDs. Shanghai Optics produces high quality TIR lenses suitable for a wide variety of different purposes.

Understanding TIR Lens Design

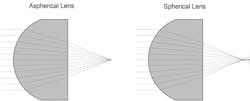

Typically TIR lenses are cone shaped compound lenses with rotational symmetry. Composed of a refractive lens inside of a reflector, they can produce smooth circular beams with minimal FWHM widths. The refractive lens receives the light, then transmits it to the reflector which processes and shapes the beam. The mechanism behind this has to do with Snell’s law and some important optical principals.

Light is refracted, or turned from its original path, at any place where it reaches an interface between two materials with different refractive indices. If the first material has a higher index of refraction than the second, Snell’s law tells us that the angle of refraction will be more than ninety degrees. Where the angle of incidence is greater than a critical angle, the light will be reflected into the material. We call this total internal reflection. The beam angle depends on the curvature of the TIR surface for your specific lens.

In order for total internal reflection to occur, the incidence angle must be greater than the critical angle.

Total internal reflection captures all light radiation leaving a source, and is therefore the most efficient method to reflect light. Providing the ultimate control of light distribution, this type of collimator is ideal for when you need a strong, targeted beam. While a simple reflector can only effect reflected light and not direct light beams, a TIR lens manages both. TIR optics placed over a LED chip will capture and focus all the light.

Lens vs. Reflector

Manufacture of TIR lenses

TIR lenses are typically manufactured from polymers (most commonly polymethyl methacrylate, acrylic or polycarbonate) through an injection-molding process. Molten polymer is injected into a carefully design mold, cooled in a controlled manner to avoid warping, and then ejected as a hardened lens and finished with precision tools. Most molds are made of hardened or pre-hardened steel, but aluminum and copper are also options for certain applications. Our efficient manufacturing process enables us to provide quality lenses at a better price point than comparable manufacturers.

Before it goes out into the world, every TIR lens manufactured by Shanghai Optics is subject to careful quality analysis. Our state of the art metrology equipment allows us to ensure each lens, optic, or optical assembly will function optimally under expected conditions.

Shanghai Optics has the capability to manufacture custom lenses per your exact specifications. Our team of optical engineers and designers can work with you through the entire process, from design and feasibility testing through prototyping and on to full scale production. Please contact us if you’d like to schedule a complimentary initial consult to discuss your project and specifications.